When it comes to Gi sheets, one size certainly doesn’t fit all. The thickness of your Gi sheet can have a significant impact on the success and longevity of your project. Whether you’re working on a roofing project, cladding, or any other application, selecting the right Gi sheet thickness is crucial.

In this comprehensive guide, we’ll walk you through everything you need to know about Gi sheet thickness.

Table of Contents

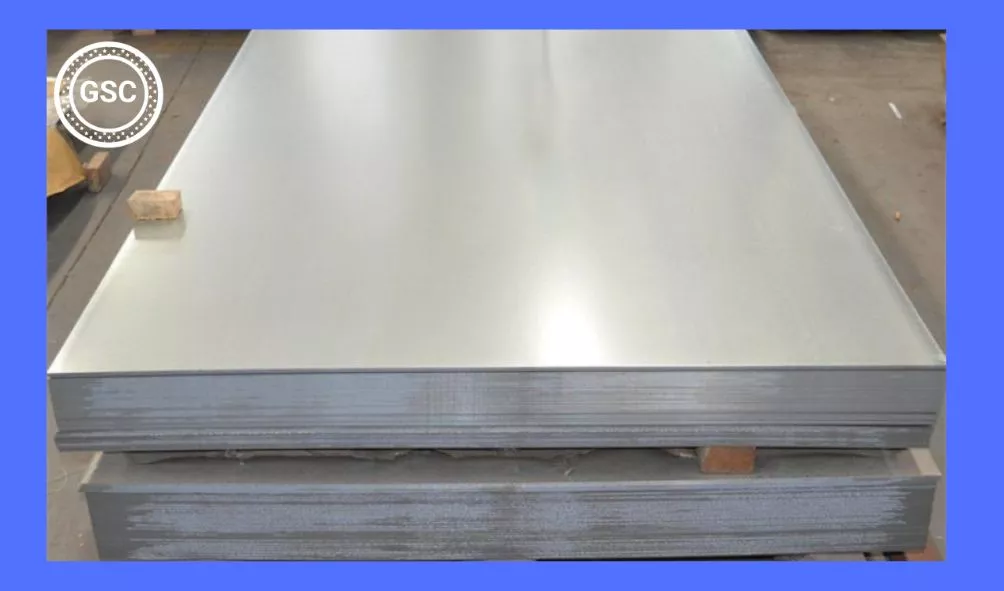

Understanding Gi Sheet Thickness

Gi roofing sheets come in a variety of thicknesses, typically measured in gauge or millimeters. The thickness you choose depends on the specific requirements of your project. Let’s explore the common Gi roofing sheet thickness options:

1. Light Gauge Galvanized Sheets (26-30 Gauge)

– These are the thinnest Gi roofing sheets available.

– Ideal for applications that require flexibility and less weight.

– Commonly used for indoor projects and decorative purposes.

2. Standard Gi Sheets (20-25 Gauge)

– The most popular choice for general-purpose applications.

– Suitable for roofing, cladding, and a wide range of outdoor projects.

– Offers a balance between durability and cost-effectiveness.

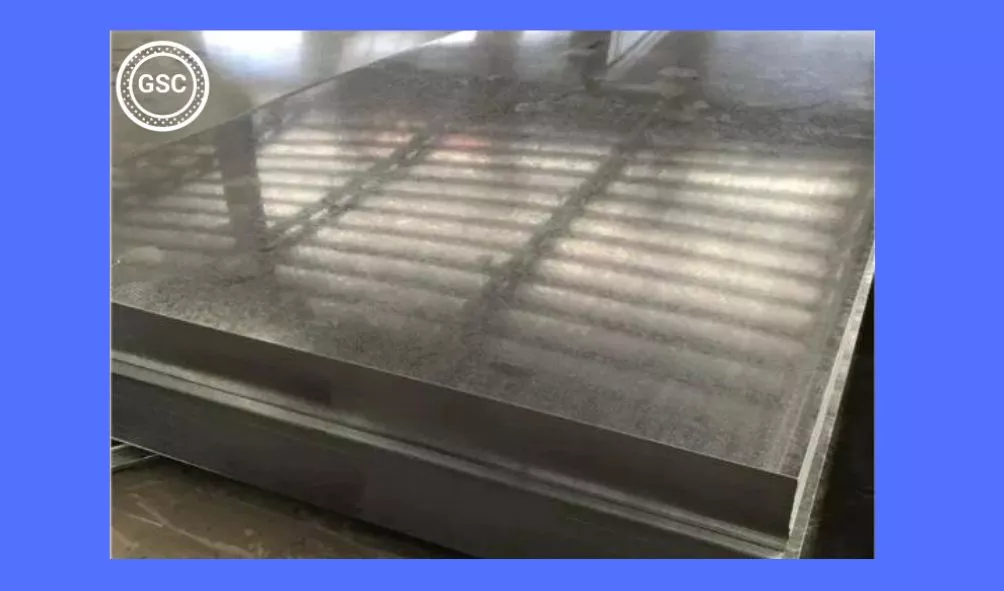

3. Heavy Gauge Galvanized Sheets (16-18 Gauge)

– Thicker Gi roofing sheets for applications demanding extra strength.

– Commonly used in industrial and heavy construction projects.

– Provides excellent resistance to wear and tear.

4. Super Heavy Gauge Gi Sheets (12-14 Gauge)

– The thickest Gi roofing sheets available, offering maximum strength.

– Ideal for applications that require utmost durability and protection.

– Typically used in heavy industrial, agricultural, and automotive projects.

Choosing the Right Thickness for Your Project

Selecting the appropriate Gi sheet thickness is a critical decision. Here are some factors to consider:

1. Project Type

– Consider the nature of your project. Is it a roofing project, cladding, or something else?

– Different applications require different levels of thickness to withstand the elements.

2. Budget

– Your budget plays a significant role in determining the Gi roofing sheet thickness.

– Thicker sheets generally cost more, but they may be essential for long-term projects.

3. Environmental Conditions

– Think about the environmental conditions the Gi roofing sheets will face.

– Harsh weather or high humidity may require thicker sheets for added protection.

4. Expected Lifespan

– How long do you want your project to last? Thicker Gi roofing sheets can extend the lifespan of your project.

Conclusion

The Galvanized roofing sheet thickness you choose can make or break your project. It’s essential to assess your specific needs, budget, and environmental factors before making a decision. By understanding the different thickness options and their suitability for various applications, you can ensure the success and longevity of your project. Make the right choice, and your Gi roofing sheets will serve you well for years to come.

If you have any more questions or need further guidance on Gi sheet thickness, don’t hesitate to contact us. Our team of experts is here to assist you in making the best choice for your project. Your satisfaction and project success are our top priorities.

3 thoughts on “The Ultimate Guide to Gi Sheet Thickness: Which One to Choose for Your Project”