When it comes to roofing materials, one name that often comes up is (Gi sheet) galvanized steel. As someone deeply involved in construction and roofing,

I’ve seen firsthand how galvanized roofing sheets have gained widespread popularity. But what is it about galvanization that makes these sheets such a reliable choice?

In this comprehensive guide, I’m going to delve into the science of galvanization and how it offers superior protection to your roofing sheets.

Table of Contents

The Marvel of Galvanization

Galvanization is the process of applying a protective layer of zinc to steel or iron to prevent corrosion and extend the material’s lifespan. This process is not just an industry secret; it’s a science that has been perfected over time to ensure that your roofing sheets can withstand the elements and the test of time.

Understanding Corrosion in Gi sheet

Before we dive into the science of galvanization, it’s essential to comprehend the primary enemy it combats – corrosion. Corrosion is the gradual destruction of materials, usually metals, through chemical reactions with the environment. The main culprit in this process is moisture, which leads to the formation of rust. In the context of roofing, corrosion is a significant concern, as it can weaken the structural integrity and aesthetics of the roof.

The Protective Power of Zinc in Gi sheet

Zinc, a bluish-white metal, is at the heart of galvanization’s magic. It’s the hero in this story. The zinc coating applied to the steel substrate creates a barrier that prevents moisture and other corrosive elements from reaching the underlying metal. This is where the science gets fascinating:

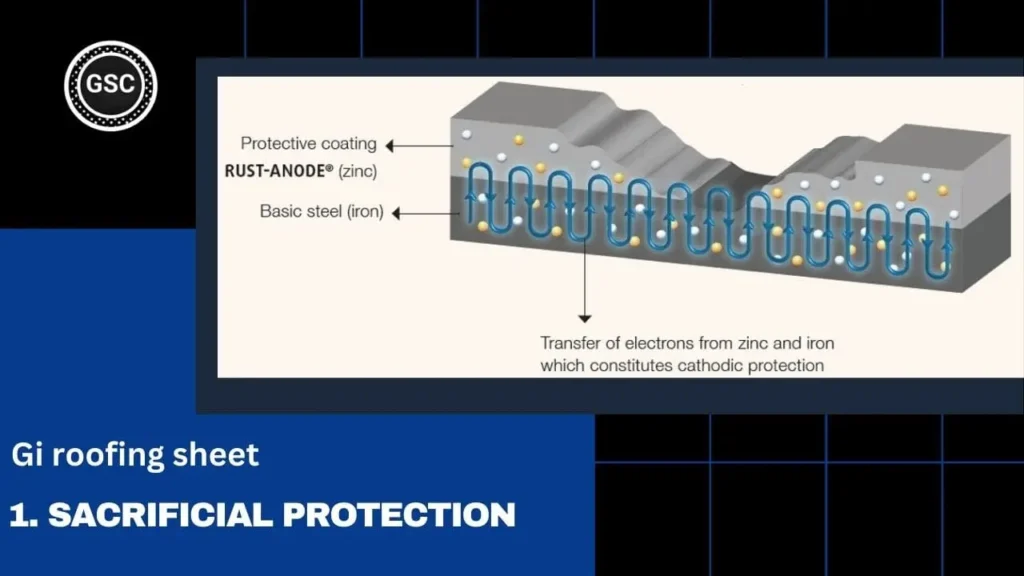

1. Sacrificial Protection

Zinc is more reactive to corrosion than iron or steel. In a process known as sacrificial protection, the zinc coating corrodes preferentially, sparing the underlying steel. This self-sacrifice ensures that the steel remains untouched and uncorroded. It’s like having a shield that takes all the hits while the core remains unscathed.

2. Formation of Zinc Oxide

When zinc reacts with oxygen and moisture, it forms zinc oxide. Zinc oxide is a stable compound that acts as a protective film over the zinc surface. This film shields the steel substrate from the environment, creating a dual-layer defense against corrosion.

3. Longevity through Galvanic Cells

The galvanization process doesn’t stop at sacrificial protection; it also harnesses the principles of galvanic cells. This is where the science of electrochemistry comes into play. Galvanic cells involve the movement of electrons between the zinc and steel. Essentially, the zinc becomes the anode (positively charged) and the steel the cathode (negatively charged) in an electrochemical circuit. The electrons flow from the anode to the cathode, further enhancing the protection of the steel.

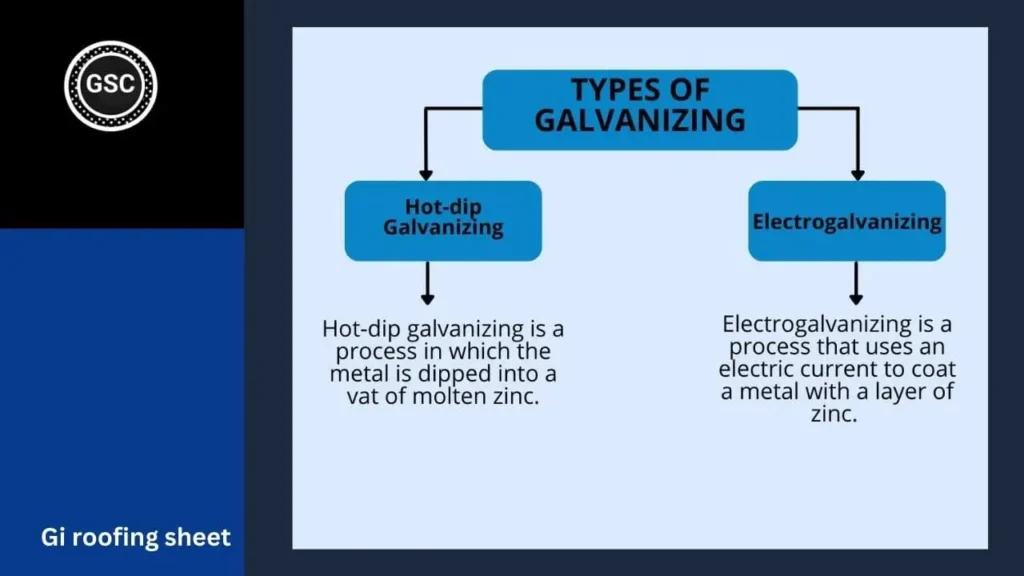

Types of Galvanization

There are different methods of applying zinc coatings, each suited for specific applications:

1. Hot-Dip Galvanization:

In this method, the steel is immersed in a bath of molten zinc. The high temperature of the bath ensures a thorough and consistent coating. Hot-dip galvanization is ideal for roofing sheets due to its robust protection.

2. Electro-Galvanization:

This method involves using an electric current to deposit a layer of zinc onto the steel. It’s often used for smaller components or parts of roofing systems.

Advantages of (Gi sheet) Galvanized Roofing Sheets

Now that you understand the science behind galvanization, let’s explore the benefits it brings to your roofing:

1. Unparalleled Corrosion Resistance: Galvanized roofing sheets are virtually immune to rust and corrosion. The sacrificial protection provided by zinc ensures that your roof remains intact and reliable.

2. Longevity: The protective zinc layer extends the life of your roofing sheets, saving you money on replacements.

Minimal Maintenance: Galvanized roofing requires minimal maintenance. A simple cleaning now and then is all that’s needed to keep it in top shape.

Environmentally Friendly: Zinc is a fully recyclable material. When the time comes to replace your roof, the old galvanized sheets can be recycled, making it an eco-conscious choice.

Aesthetic Appeal: Galvanized roofing sheets come in various finishes and colors, allowing you to choose a style that matches your architectural preferences.

In Conclusion

As a professional in the field, I can attest to the effectiveness of galvanized roofing sheets in providing reliable protection for your home. The science of galvanization is a testament to human innovation and our ability to combat corrosion, ensuring that your roof stands strong against the elements. When you choose galvanized roofing sheets, you’re not just selecting a material; you’re opting for a scientifically proven solution that offers longevity, durability, and peace of mind.